Biogas plants are an indispensable part of achieving the climate protection goals. For operators of biogas plants, safety and profitability are the key points of success. Monitoring and measurement in production are therefore essential. High quality standards must be observed. This applies in particular to the precise measurement of the standard volume flow and the flow rate of the biogas.

The following requirements are relevant for biogas meters:

- The biogas plant must be equipped with a suitable, tamper-proof measuring device (certification by a state-recognized testing agency, if necessary with volume corrector for conversion to the normal state).

- The gas quantities are to be registered cumulatively in a suitable (hourly) load profile. The measured value must be readable on the measuring device at all times.

- The measuring device must be installed so that the greatest possible measuring accuracy and availability (against failure) is guaranteed.

- The position of the measuring device must be selected so that the total quantities of the biogas generated by the biogas production plant are recorded and correspond to the installation conditions of the manufacturer. A certificate from the specialist company must be presented.

- Due to the high methane content (50 - 60%), devices must be used for use in potentially explosive areas (explosion protection according to ATEX)

.

.

What can we measure?

- Mass flow

- Total mass flow

- Flow velocity

- Gas temperature

Which device is suitable?

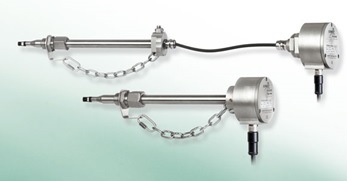

Flow sensor SS 20.600 ![]()

LED measured value display MD 10.015

Due to the large flow measuring range of the SS20.600 chamber head sensor, it is particularly suitable for biogas plants. The calorimetric chamber head sensor measures flow velocities from 0.2 m/s to 220 m/s.

Due to the large flow measuring range of the SS20.600 chamber head sensor, it is particularly suitable for biogas plants. The calorimetric chamber head sensor measures flow velocities from 0.2 m/s to 220 m/s.- The SS20.600 delivers precise measurement results (±1% for gases from 3%) even at high overpressures and over wide temperature ranges.

- To protect against aggressive gases and dust, the sensors in the chamber head of the sensor are covered with a thin layer of glass.

- In addition to the flow velocity, the sensor also measures the medium temperature up to 120 °C.

- If the standard version of 16 bar overpressure is not sufficient, a version up to 40 bar can be selected.

- The optional ATEX version SS 20.600 Ex is designed for use in an explosive gas atmosphere in Zone 2.

The SS20.600 can therefore be used flexibly for different applications in biogas plants:

- Control of gas and air supply

- Control of the exhaust gases

- Control of the air circulation

- Control of drying processes

- Determination of gas volumes

What must be specified when ordering the devices?

- Gas quality and composition

- Pollution

- Moisture (non-condensing)

- Pressure differences

- Temperature fluctuations

Renewable Energy Law (EEG)

The new Renewable Energy Sources Act (EEG), effective since August 1, 2014, ensures the profitability of existing biomass plants. The expansion of the biomass focuses on the use of residues (e.g. liquid manure and waste materials). Details on the promotion of biogas plants (market premium and feed-in tariff) can be found in the currently valid legal text on the website of the Federal Ministry of Justice and Consumer Protection and the Federal Ministry for Economic Affairs and Energy. EnergieAgentur.NRW GmbH provides a commented summary.

Further Information:

- Fachverband Biogas e.V.

- Informationsportal der Agentur für Erneuerbare Energie

- Deutschen Energie-Agentur GmbH (dena)

- Biomasseportal der EnergieAgentur.NRW

- Netzwerk Biomasse

- Bioenergieatlas.NRW

- Landwirtschaftskammer NRW

- Fachagentur Nachwachsende Rohstoffe e.V.

- You can subscribe to the biogas newsletter for authorities of the Biogas Association here: behoerdennewsletter@biogas.org

Practical examples

Biogas plant Thai Engineering Consultant Company PAPOP Col. Ltd. Biogas plant Thai Engineering Consultant Company PAPOP Col. Ltd. |

Twenning TwenningAhlde 20 48488 Emsbüren |

Geerdes GeerdesBeestener Str. 1 49832 Messingen |

Biogas Hövels Biogas HövelsAhlde 122 48488 Emsbüren |

Warbur WarburSteider Str. 92 48499 Salzbergen |

|

|

| Attachment | Size |

|---|---|

| Data-sheet SS20.600 | 649.38 KB |

| Data-sheet LED measured value display MD | 168 KB |

Test facility:

Test facility: