In numerous applications for level monitoring of liquid media, the use of float switches is prohibited. Typical applications are contaminated media and turbulence in the medium, which can block the float. In these cases, optoelectronic level sensors are often used.

Optoelectronic level monitoring has the following advantages:

No mechanically moving parts

PNP transistor output

High accuracy (± 0.5mm)

Compact design

Very good price-performance ratio

Schmidt Mess- und Regeltechnik offers you a comprehensive portfolio for these applications:

| OG 01 | OG 02 | OG 04 | OG 05 | OG 051 | OG 052 | |

| Applications | standard | standard | refrigeration techinique | high temperature | Ex areas | commercial vehicles and marine engines |

| Special features | compact design | switch length up to 3000mm | prismatic glass melted into the steel housing | up to 170°C, optional higher | with Atex approval | vibration and temperature shock resistant |

| Pressure max. | 10 bar | 25 bar | 40 bar, optional higher | 25 bar | 25 bar | 25 bar |

| Medium temperature max. | 100°C | 100°C | -40°C ... +100°C | 170°C, optional higher | 135°C | 130°C, optional higher |

| Approvals | Atex, IEC | German Lloyd |

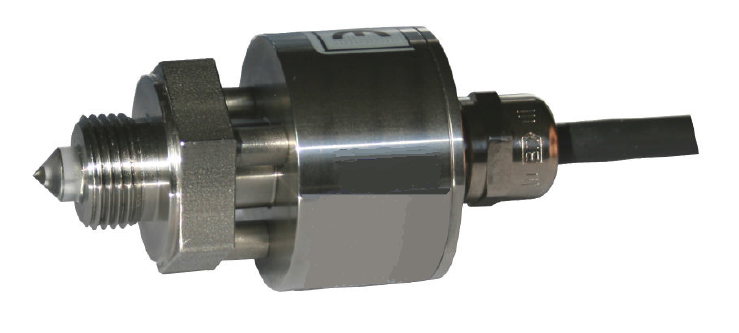

For standard applications OG 01 and OG 02

| We use devices OG 01 and OG 02 for standard optoelectronic applications (liquids such as oils, water, distilled water, aqueous media, for foam detection). | |

|

Applies to both devices:

Temperature max. 100°C

Accuracy ±0.5mm

No moving parts

Function independent of position

Responsiveness adjustable

High compressive strength (OG01: up to max 10 bar, OG02: up to max 25 bar, optional higher)

OG 02 is also available with freely selectable switch lengths from 65 mm to 3,000 mm. This enables an optimal adaptation to the application-specific requirements.

For refrigeration technique OG 04

This sensor can be used with various refrigerants. The prismatic glass is melted into the steel housing, there are no seals. Therefore, no attack by the refrigerant is possible.

Further features:

High pressure resistance, up to 40 bar, optionally up to 100 bar

Can be used down to -40 °C

Responsiveness adjustable

For high temperatures OG 05

The OG 05 was developed for particularly high media temperatures. It can be used in a range from -40 to 170 °C. On request, we also supply special versions for the range above 170 °C.

For these applications, the OG 05 is equipped with a stainless steel housing.

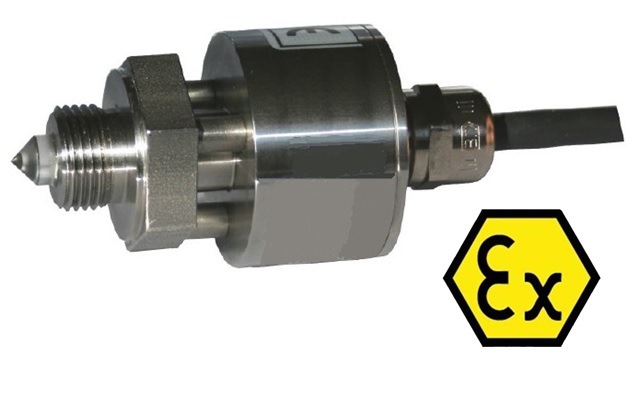

For Ex areas OG 051

New at Schmidt Mess- und Regeltechnik: The optoelectronic level sensor OG 051 is designed as an explosion-proof version for zones 0 and 1 (ATEX approval according to protection type II1 / 2G Ex ia IIC T4Ga / Gb) for medium temperatures up to 135 ° C.

The parts of the housing that come into contact with the medium are made of stainless steel. The prism material is borosilicate glass. The device can be supplied with numerous fastening threads (G ⅜“, G ½“, NPT ½ “, M18x1,5 M12x1, M12x1,75, M14x1,5, M14x1,75).

Current switching output:

Supply -7.5 … 30 V DC

Low: >4mA up to <10mA; High: >12mA up to 18mA

Errors: <4mA, >20mA

For commercial vehicles and marine engines OG 052

Special features:

Special features:

The optical level switch type OG 052 is characterized by its extremely good mechanical and electronic stability as well as the high temperature shock resistance, reliability and its exact switching accuracy even at high temperatures.

Due to the compact design, installation is possible even in confined spaces.

The OG 052 was certified by Gemanischer Lloyd for shipbuilding applications.

Further festures

Robust design, made of stainless steel

Vibration and temperature shock resistant

Media temperature max. 130 °C, pressure 25 bar

Approval: German Lloyd

Applications

The OG 052 was developed for extreme operating conditions and is often used for oil detection in commercial vehicles, machine tools, construction machines, agricultural machinery, rail vehicles, compressors, pumps, hydraulic units and motors.