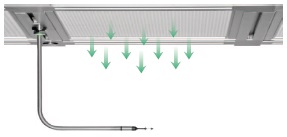

Monitor the flow in cleanrooms and clean areas

A direction-defined air flow in clean rooms protects products from contamination and disruptive particles are safely removed. For this purpose, a uniform air flow from the ceiling to the floor ("directed, low-turbulence displacement flow") is maintained in clean rooms with high cleanliness classes. The monitoring range extends from 0.36 to 0.54 m / s flow velocity (EU GMP guidelines, Annex 1 in class A). This measurement is carried out on the clean room side using terminal filters. Since the air circulation is throttled during downtimes, high-precision measurement of the air speed from 0.1 m / s is necessary.

Measurement professionals in the field of laminar flow

Two proven measurement professionals for laminar flow monitoring and control - highly precise and quickly installed. The two flow sensors are already established on the market. The optimization and successful implementation of important market requirements now make plant operation even safer, easier and more intuitive.

LF status indicator integrated

For laminar flow monitoring and control, users repeatedly demand three functions that are important to them:

Operating status display directly visible on the sensor.

Monitoring of the standard permitted speed interval of 0.45 m / s ± 20% with optical signaling directly on the sensor (LF status indicator).

Serial number of the sensor visible directly on the sensor, even when installed.

Sensor status and optional LF status visualized by LED light ring

With the revision of the existing flow sensors, all three customer requirements were successfully implemented. The two improved variants with the suffix "LED" now have an LED light ring that visualizes the corresponding sensor status. The operating status display has been implemented in general, the LF status indicator is designed as an order option because this function is not always required.

The luminous colors stand for the following operating states:

| Signalising Sensor status | ||

green continuous light | Sensor ready for operation | |

| red flashing | Sensor malfunction |

| red contibuous light | Analog output connected incorrectly |

orange flashing | Measured value outside the monitoring window 0.45 m/s ± 20% | |

Safe operation guaranteed and revision easier

This enables the clean room operator to ensure safe operation at a glance. In addition, the serial number has been moved to a location that is always visible, so that the system operator can use the serial number to directly assign the sensor to his documentation during revision work without having to remove the sensor.

Highlights of the SS 20.415 LED and SS 20.515 LED:

Highly precise measurement of the flow velocity or the standard volume flow (SS 20.515 LED additionally with output of the temperature)

Highest reproducibility of the measurement results

Highly integrated evaluation electronics in the sensor tube - no further transmitters required

Integrated operating status display via LED light ring

Optional LF status indicator "0.45 m / s ± 20%" using an LED signal

Suitable for clean rooms, easy to clean

Easy installation and commissioning (visual support during commissioning, LED signal)

5 mechanical mounting options (straight wall and angled ceiling mounting possible)

Typical areas of application for the SS 20.415 LED and SS 20.515 LED:

Precise measurement of the smallest air speeds

Clean room and pharmaceuticals (laminar flow monitoring and control, laboratory systems and fume cupboards)

Packaging technology

Delivery time: 2 weeks

| Attachment | Size |

|---|---|

| Data-sheet anemometer SS 20.415LED | 171.59 KB |

| Data-sheet anemometer SS 20.515LED | 194.85 KB |