03.04.2012

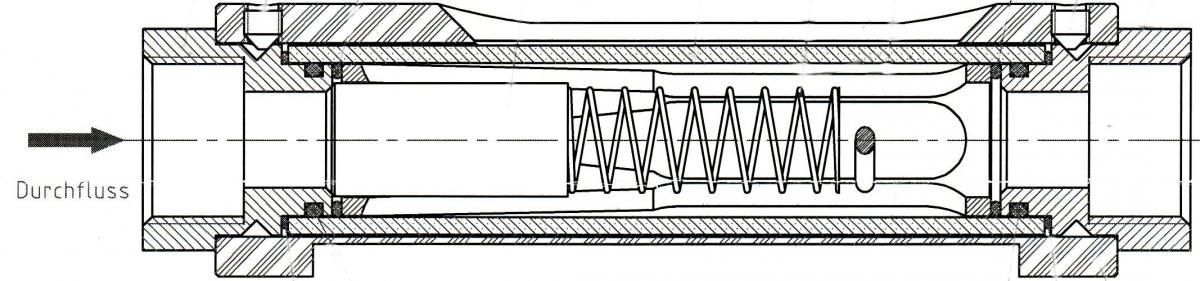

The flow meter / flow monitor DUG works according to the variable area principle. The usual conical measuring tube was replaced by a slot nozzle. This special construction enables the installation of a special compression spring, which exerts an additional force on the float.

| The compression spring | |

|

DUG construction drawing with compression spring |

|

|

|

|

DUG features

- Robust design: aluminum sleeve protects the sight glass

- Compact design: overall length of 132 - 222 mm

- Large measuring range: (depending on the measuring range)

- Independent of position: spring returns the float to its starting position

- Sight glass: high quality borosilicate glass

- Compressive strength: operating pressure max. 10 bar

- Temperature: 120 ° C (standard version), 160 ° C (high temperature version)

- Explosion protection: Explosion-proof design according to ATEX available

- Encapsulated float: Magnets (hard ferrite) not in contact with media

Areas of application for the DUG float

DUG is already used in all industries for flow measurement / flow monitoring. Here are some practical examples in the industries

| Process industry: |

|

| Plant engineering and construction: |

|

| Process technology: |

|

| Water treatment: |

|

| Energy generation: |

|

DUG is also used in the mechanical engineering, chemical, pharmaceutical, medical technology and laser technology sectors.

DUG delivery time: 2 weeks

| Attachment | Size |

|---|---|

| Operating instruction flowmeter / flow switch DUG | 244.75 KB |

Different language link