The question often arises as to the most suitable monitoring of liquid levels: float switch, optoelectronic sensor or tuning fork switch?

Float switches work with a moving float that moves depending on the liquid level on a sliding tube and switches the reed contact located in this tube. Float switches are certified for universal applicability. They are generally reliable and economical. If the pressure or temperature limits are exceeded and the viscosities (oils) are high, or if the densities required for float switches are undershot, the use of optoelectronic level switches is an alternative.

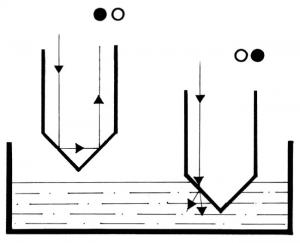

An optoelectronic level switch uses the different refractive indices of liquid and air. Due to its shape, an outgoing light beam is reflected in a glass rod so that it switches a receiver. If the glass rod is immersed in a liquid, the light beam is no longer reflected, but continues in the optically dense medium. The light on the receiver stays off and leads to a false signal.

Our OG series optoelectronic level switches can be used up to temperatures of 170 ° C and pressures up to 100 bar. The devices are so reliable that even adhering drops do not lead to incorrect switching. In the case of milky liquids, the devices are also optically modified.

Thanks to the high level of functional reliability, optoelectronic level switches are now often the cheapest solution even for standard applications when it comes to deciding on float switches, optoelectronic level switches or tuning fork switches.

We would be happy to support you. Please contact us.